-

Lantian Machinery

- Home

-

Products

- Case

- News

- Company Information

- Certificates

- Contact Us

Gongyi Lantian Machanical Plant > Products > Dryer > Views

Posted at: 2018 / 06 / 08 by: Admin views:

1. The coal industry: Coal slurry, coal, flotation clean coal, mixed clean coal etc.

2. The construction industry: Blast furnace slag, clay, Peng Yun soil, lime stone, sand, quartz stone etc.

3. Ore processing industry: Various metal concentrates, slag, tailings etc.

4. Chemical industry: Non-drying heat sensitive materials.

Coal slime dryers developed based on the rotary dryer. It can be widely used in:

1. The coal industry: Coal slurry, coal, flotation clean coal, mixed clean coal etc.

2. The construction industry: Blast furnace slag, clay, Peng Yun soil, lime stone, sand, quartz stone etc.

3. Ore processing industry: Various metal concentrates, slag, tailings etc.

4. Chemical industry: Non-drying heat sensitive materials.

Features:

1.Coal slime dryers has Strong anti overload ability, large handling capacity, less fuel consumption, low dry cost.

2. Adopt downstream drying method, the hot air with wet materials enter into the dryer by the same side, can use the high temperature air to achieve very high evaporation strength, the exist temperature of dryer is low, the thermal efficiency is high.

3. According to different materials' properties change operation parameters, make the material in the dryer cylinder body can form a stable all broken fabric curtain, qualitative heat is more fully.

4.New feeding and discharging device eliminate the feeding jams, discontinuous, uneven and returning charge etc. Phenomenon, reduce the load of dust removal system.

5. New internal structure, strengthened the already scattered materials' cleaning and heat transfer effect, eliminated the sticky phenomenon in cylinder body's inner wall, make material moisture, sticky adaptability more stronger.

6. Dryer has realized "zero horizontal thrust", greatly reduce the wear of block roller, cylinder's operation is smooth and reliable;

7.Drying machine adopts "center-adjusting roller device", make the cooperation of roller and rolling ring always show linear contact which greatly reduces the wear and power consumption.

8. According to customer's request control product size and moisture, when dry slime, the moisture can reach below 8%, particle size can be controlled below 8mm.

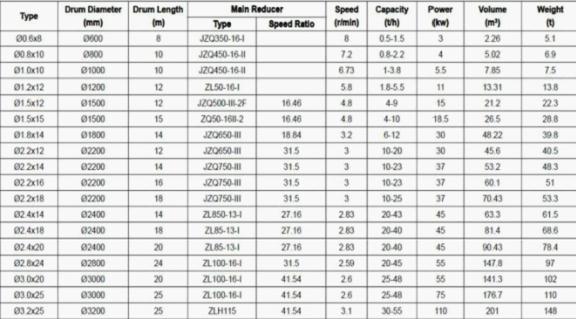

Technical Parameter:

[Dryer] >>

<< Sand dryer